Welcome to GoBozor

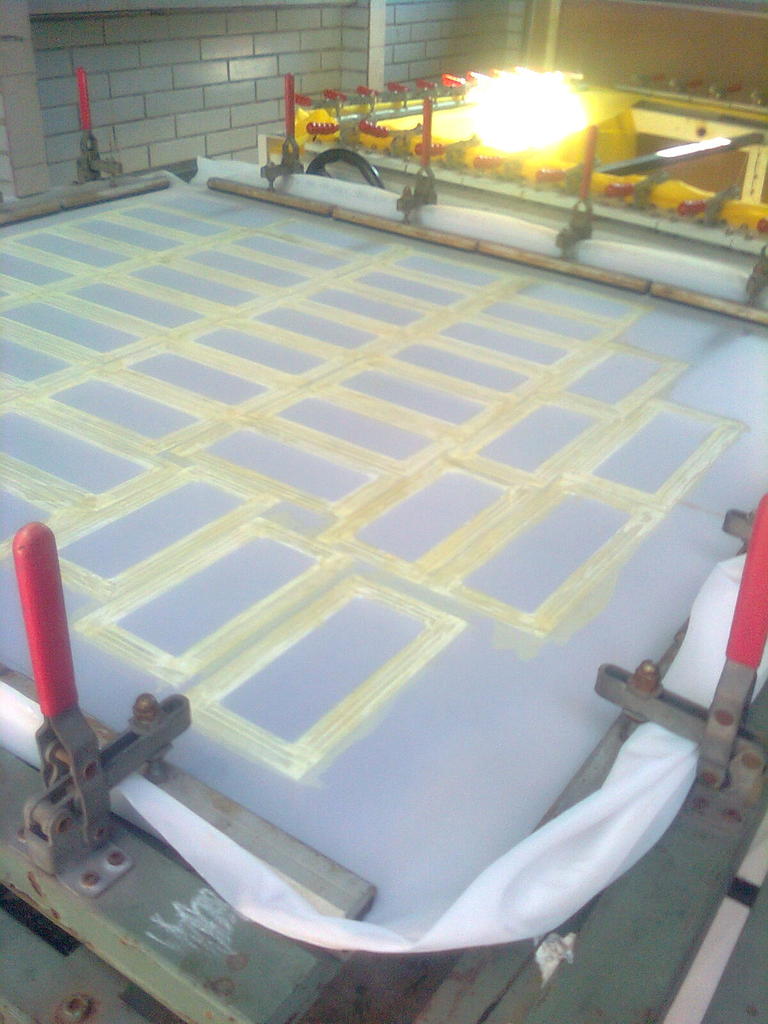

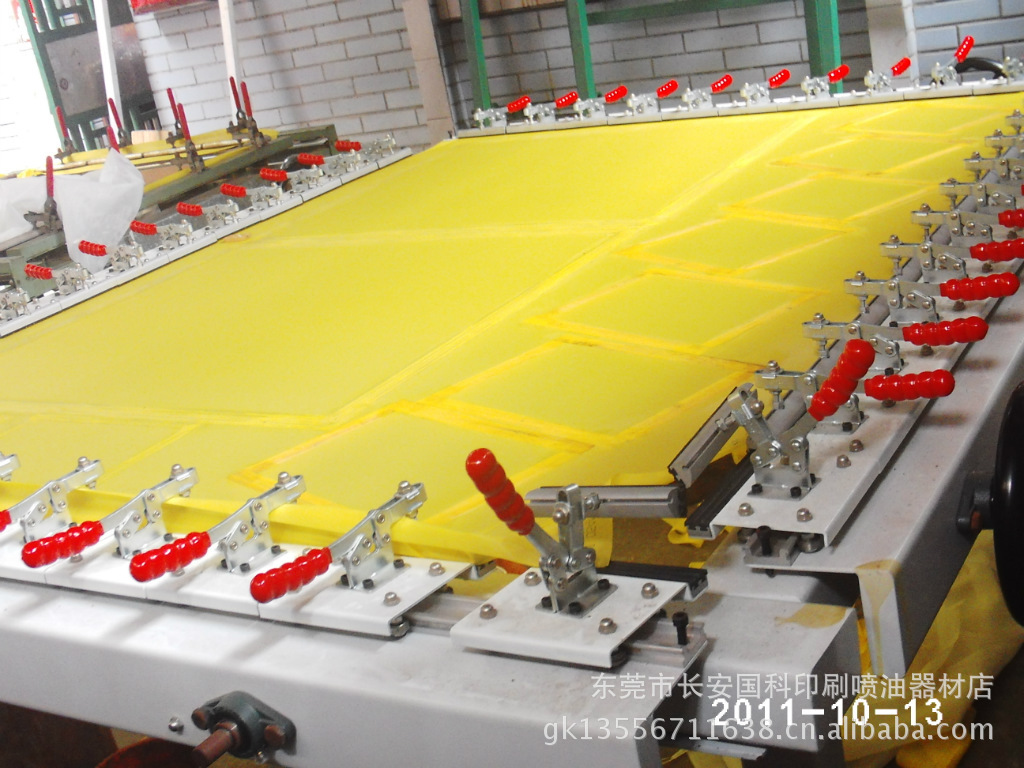

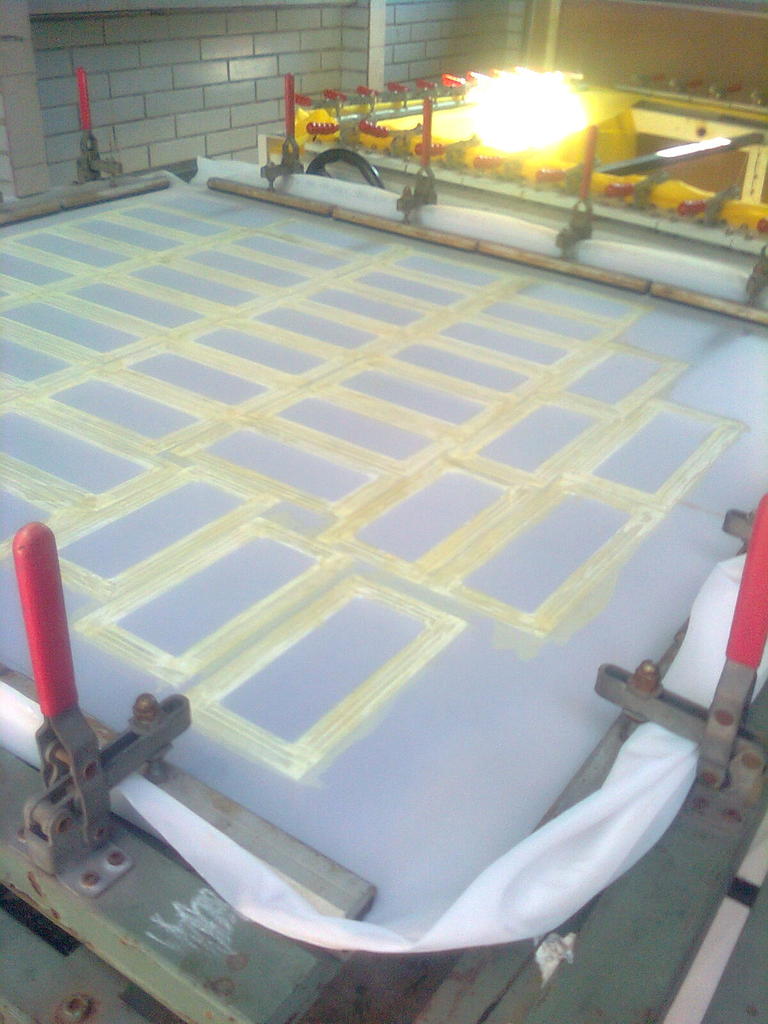

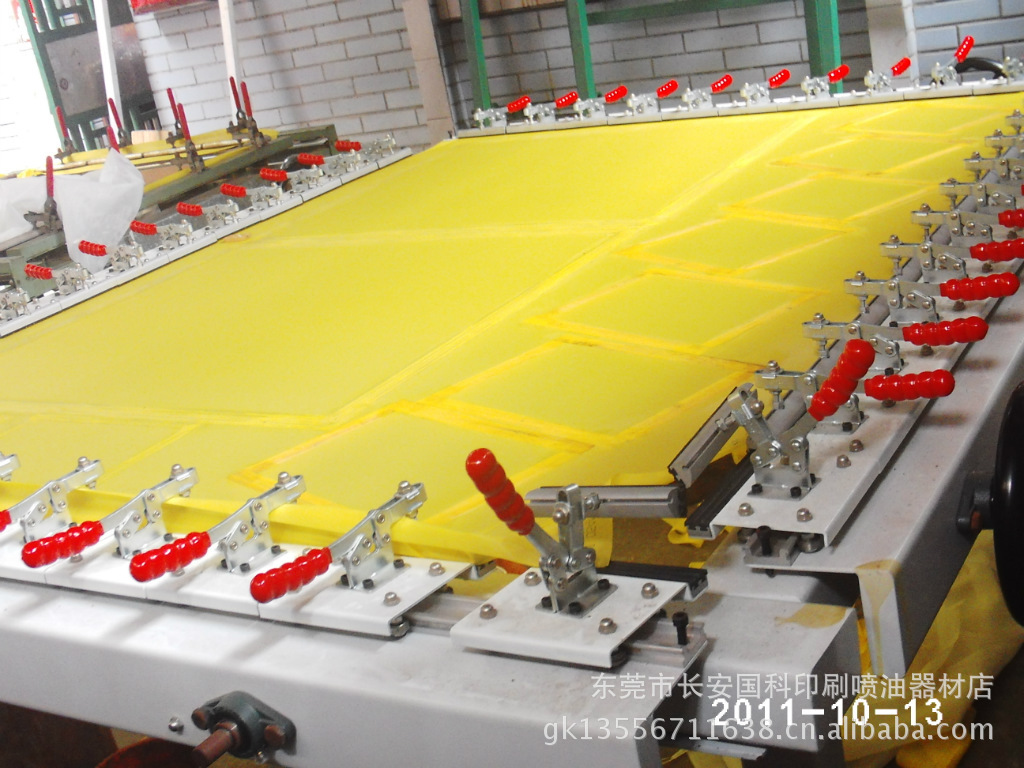

Wholesale circuit board screen printing mesh special mesh high tension high temperature resistant mesh uniform cost-effective

Price section

Price from:

61,127 so'm

Specification model

39T100 mesh 158*500 * Full Volume * 158

43T110 mesh 158*500 * Full Volume * 158

77T190 mesh 158*500 * Full Volume * 158

80T200 mesh 158*500 * Full Volume * 158

100T250 mesh 158*500 * Full Volume * 158

120T300 mesh 158*500 * Full Volume * 158

140T350 mesh 158*500 * Full Volume * 158

165T420 mesh 158*500 * Full Volume * 158

39T100 mesh 158*10 * sample * 1

Guaranteed delivery time

If we are 45 days late, you will receive your order for free. More details

Always in touch with you

We will answer any questions every day.

Secure payment in a convenient way

We will accept payment by any card

BNPL available

About the product

Characteristic

- Item No.

DPP43T

- Composition and content

100% polyester

- Alias

Silk screen mesh

- Warp and Weft knitting

Warp knitting

- Quality Standard

European Standards Association (EN)

- Specific use

Industrial

Description

本公司销售DPP丝印线路板专用网纱,该网纱张力高,稳定性好,横纬线分布佳,是印刷线路板极佳网纱之一,规格分别有16T40目-165T420目间,宽度为127CM/158CM/162CM等,欢迎来电咨询.

高品质拉网步骤:网框清理--水平检校--涂底层胶--拉网--测张力--涂粘胶--下网、封边--储存作业说明因网框重复使用,网框四周有残存之粘胶、网纱等杂物,必须清除干净,以免影响网纱与网框之粘合力将网框放置于平台(需水平)检查网框是否变形,如有变形则需进行整平处理将清理好,未变形网框与网纱接着面溥而均匀的涂一层南宝权脂(无需加硬化剂)以增强拉网后网纱与网框粘合力待第一次涂胶约10分钟后,将网框放置于拉网台,并调整好相对之位置及高度选择网目,松开四周夹嘴,将网纱平铺在框上,然后将网纱均匀夹进夹嘴里,不能有起皱,注意四角要有较松余网纱,夹嘴一定需锁紧,夹子与夹子之间不能有间隙(自动升架、手动拉网为例)拉网:第一次张力26,静置5分钟张力为24;第二次张力28,静置5分钟张力26;第三次张力32,静置5分钟张力为30;第四次校正5点张力32,静置20分钟后上胶张力30;15分钟胶固化下网张力28,静置72小时后方可制作网版(以一米×一米全自动生产线使用网版为例)。1、纵向拉开 收回 3、纵向拉开 收回2、横向拉开 收回 4、横向拉开 收回纵向横向同步拉开,一直拉到所需张力时则刷胶,常用网网纱张力为(100T、110T、120T均为30±2牛顿)(77T、51T均为35±2牛顿)(24T为50±2牛顿)将已调好的胶水用小毛刷均匀地刷在网框与网纱接着面上方,不可将胶水掉进网版中间部位,待胶8分钟干燥后,可用刮刀胶在涂胶面将未完全贴合之地方压紧贴合约10分钟左右胶水彻底干燥后(应采用开放式吹风加强干燥)才可下网.

Characters

Properties

- Item No.

DPP43T

- Composition and content

100% polyester

- Alias

Silk screen mesh

- Warp and Weft knitting

Warp knitting

Description

本公司销售DPP丝印线路板专用网纱,该网纱张力高,稳定性好,横纬线分布佳,是印刷线路板极佳网纱之一,规格分别有16T40目-165T420目间,宽度为127CM/158CM/162CM等,欢迎来电咨询.

高品质拉网步骤:网框清理--水平检校--涂底层胶--拉网--测张力--涂粘胶--下网、封边--储存作业说明因网框重复使用,网框四周有残存之粘胶、网纱等杂物,必须清除干净,以免影响网纱与网框之粘合力将网框放置于平台(需水平)检查网框是否变形,如有变形则需进行整平处理将清理好,未变形网框与网纱接着面溥而均匀的涂一层南宝权脂(无需加硬化剂)以增强拉网后网纱与网框粘合力待第一次涂胶约10分钟后,将网框放置于拉网台,并调整好相对之位置及高度选择网目,松开四周夹嘴,将网纱平铺在框上,然后将网纱均匀夹进夹嘴里,不能有起皱,注意四角要有较松余网纱,夹嘴一定需锁紧,夹子与夹子之间不能有间隙(自动升架、手动拉网为例)拉网:第一次张力26,静置5分钟张力为24;第二次张力28,静置5分钟张力26;第三次张力32,静置5分钟张力为30;第四次校正5点张力32,静置20分钟后上胶张力30;15分钟胶固化下网张力28,静置72小时后方可制作网版(以一米×一米全自动生产线使用网版为例)。1、纵向拉开 收回 3、纵向拉开 收回2、横向拉开 收回 4、横向拉开 收回纵向横向同步拉开,一直拉到所需张力时则刷胶,常用网网纱张力为(100T、110T、120T均为30±2牛顿)(77T、51T均为35±2牛顿)(24T为50±2牛顿)将已调好的胶水用小毛刷均匀地刷在网框与网纱接着面上方,不可将胶水掉进网版中间部位,待胶8分钟干燥后,可用刮刀胶在涂胶面将未完全贴合之地方压紧贴合约10分钟左右胶水彻底干燥后(应采用开放式吹风加强干燥)才可下网.