Welcome to GoBozor

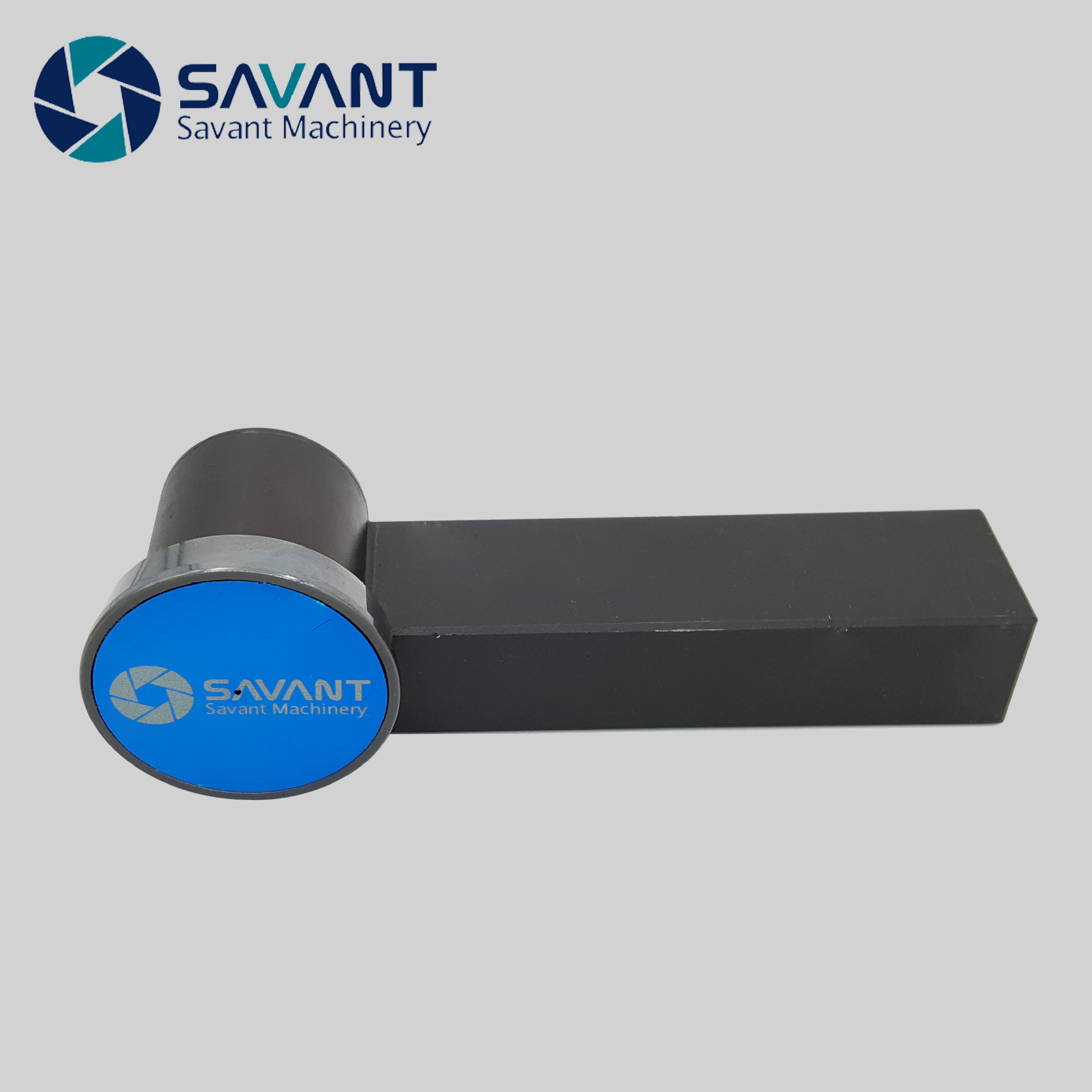

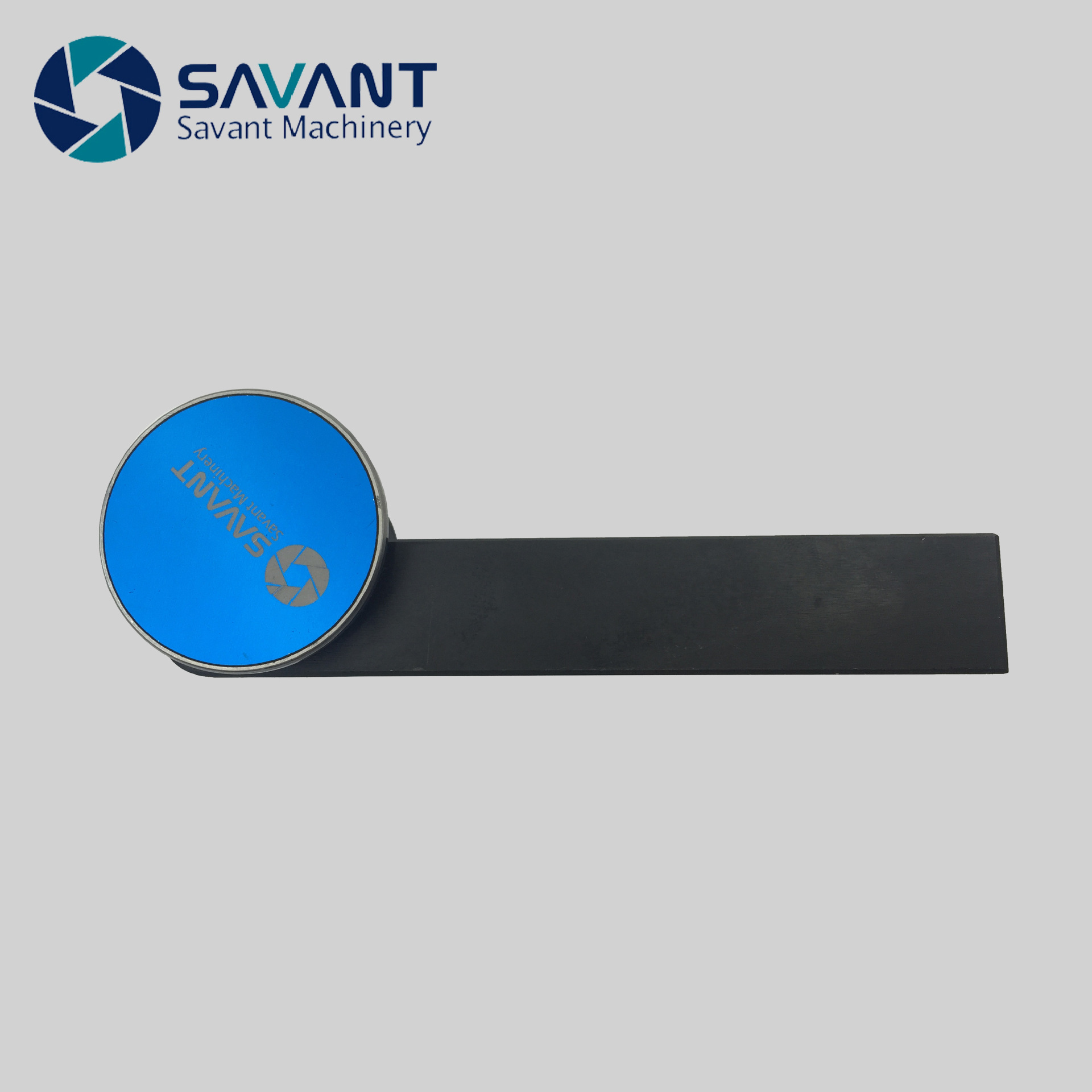

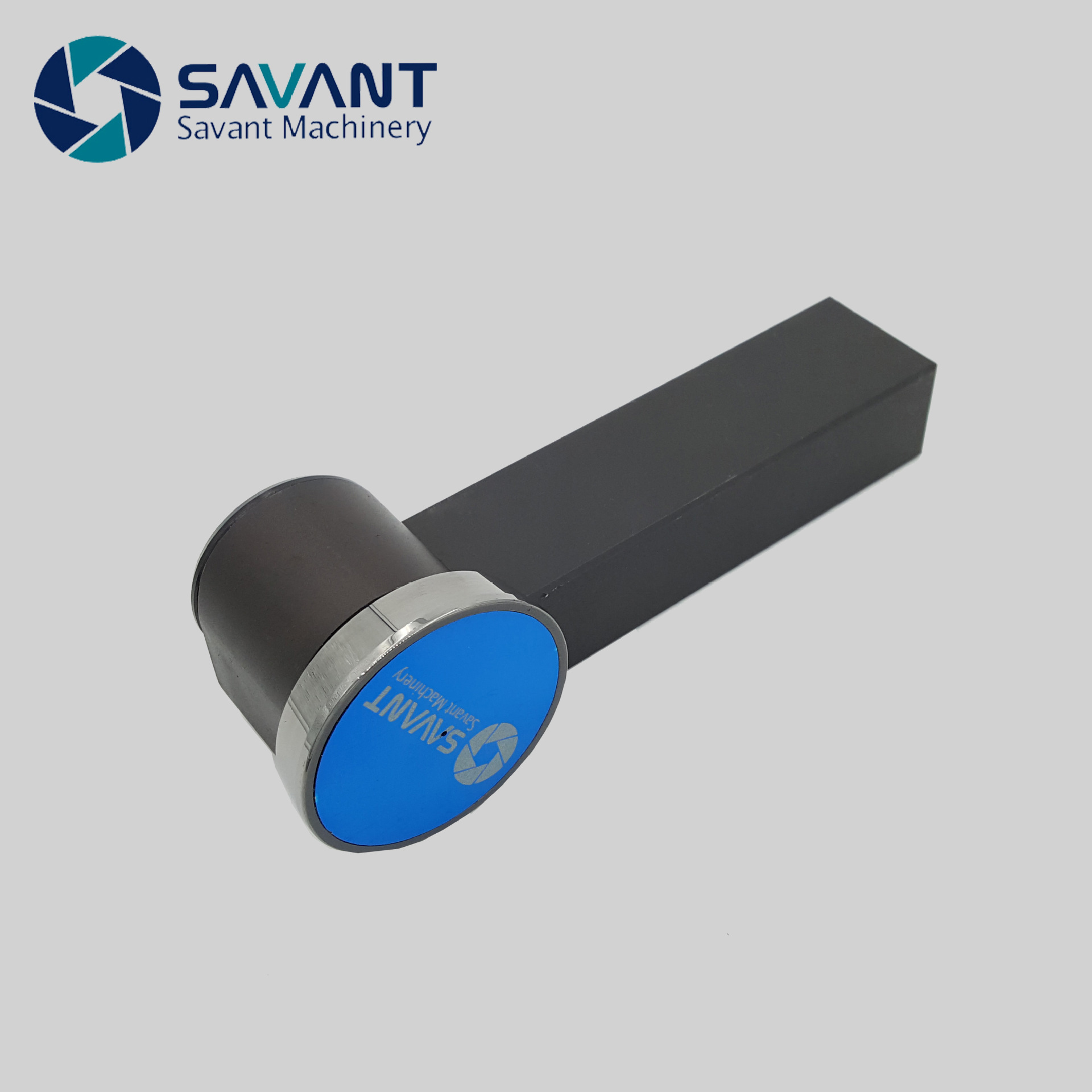

Machining Center External Cylindrical Rolling Cutter Outer Diameter Extrusion Hard Alloy Roller Type Rolling Cutter W1250

Price section

Price from:

4,702,060 so'm

Specifications

W1250

Guaranteed delivery time

If we are 45 days late, you will receive your order for free. More details

Always in touch with you

We will answer any questions every day.

Secure payment in a convenient way

We will accept payment by any card

BNPL available

About the product

Characteristic

- Material

Cemented carbide

- Origin

Wuxi

- Item No.

W1250

- Processing range

20-400

- Accuracy

1

- Model

W1250

- Diameter

1

- Standard No.

18961863005

- Product category

Rolling Knife

- Whether to import

No

- Order No.

Carbide roller type hobbing knife

Description

外圆滚压刀 外径挤光 硬质合金滚轮式 滚光刀 W1250

单轮外径滚压刀

一、滚压加工的特点

一、滚压加工的特点

1、硬质合金滚轮使用寿命长

2、滚压效率高,光洁度高

3、能提高加工件表面硬度

二、滚压用量

1、滚压线速度:V=10-25m/min(可提高)

2、进给量:S=0.1-0.2mm/rev

3、滚压过盈量:0.15mm(单边)

4、实际压入量:0.01-0.02mm

三、注意事项

1、滚轮中心与工件轴中心应等高

2、滚压表面与工件轴表面在滚压时须保证清洁,无油污

3、滚压须一次完成,多次滚压会产生斑点和脱皮

4、滚压的小平面与零件轴面应有1°-1.5°的交叉(双轴心交叉)

5、润滑滚压时,液体(建议用煤油或机油)须清洁,滚压效果会较好。

Characters

Properties

- Material

Cemented carbide

- Origin

Wuxi

- Item No.

W1250

- Processing range

20-400

Description

外圆滚压刀 外径挤光 硬质合金滚轮式 滚光刀 W1250

单轮外径滚压刀

一、滚压加工的特点

一、滚压加工的特点

1、硬质合金滚轮使用寿命长

2、滚压效率高,光洁度高

3、能提高加工件表面硬度

二、滚压用量

1、滚压线速度:V=10-25m/min(可提高)

2、进给量:S=0.1-0.2mm/rev

3、滚压过盈量:0.15mm(单边)

4、实际压入量:0.01-0.02mm

三、注意事项

1、滚轮中心与工件轴中心应等高

2、滚压表面与工件轴表面在滚压时须保证清洁,无油污

3、滚压须一次完成,多次滚压会产生斑点和脱皮

4、滚压的小平面与零件轴面应有1°-1.5°的交叉(双轴心交叉)

5、润滑滚压时,液体(建议用煤油或机油)须清洁,滚压效果会较好。