Welcome to GoBozor

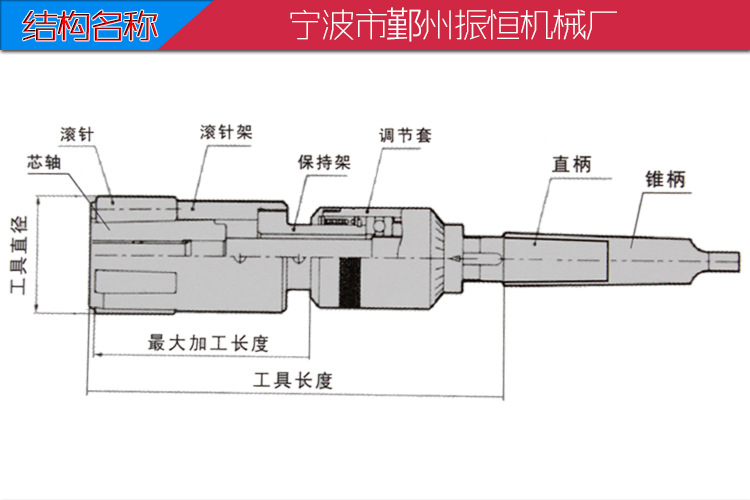

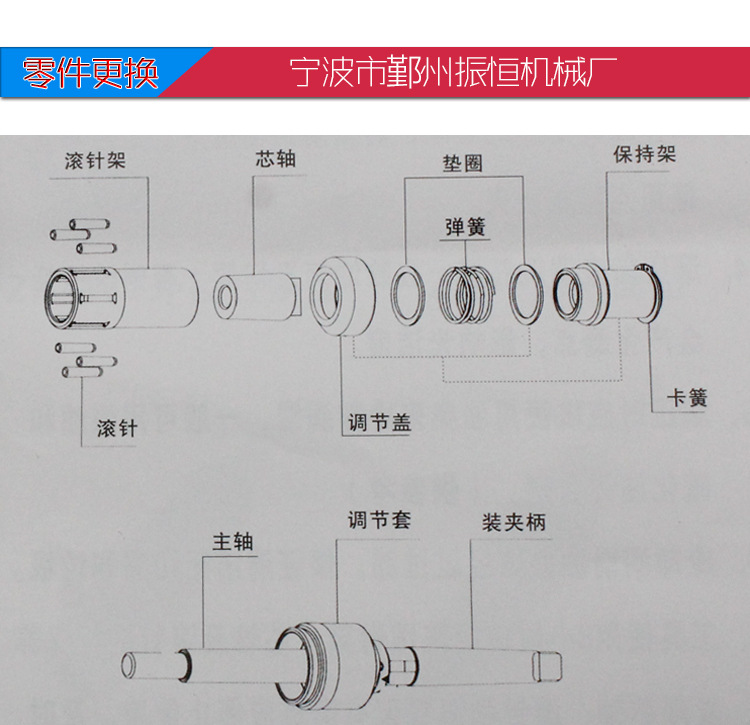

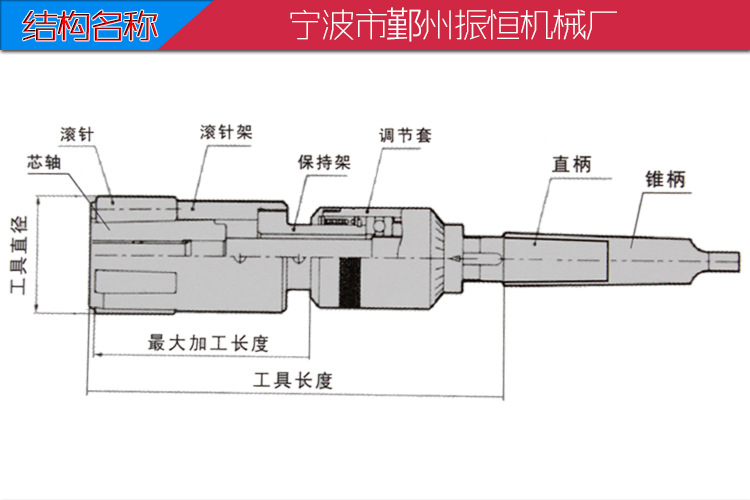

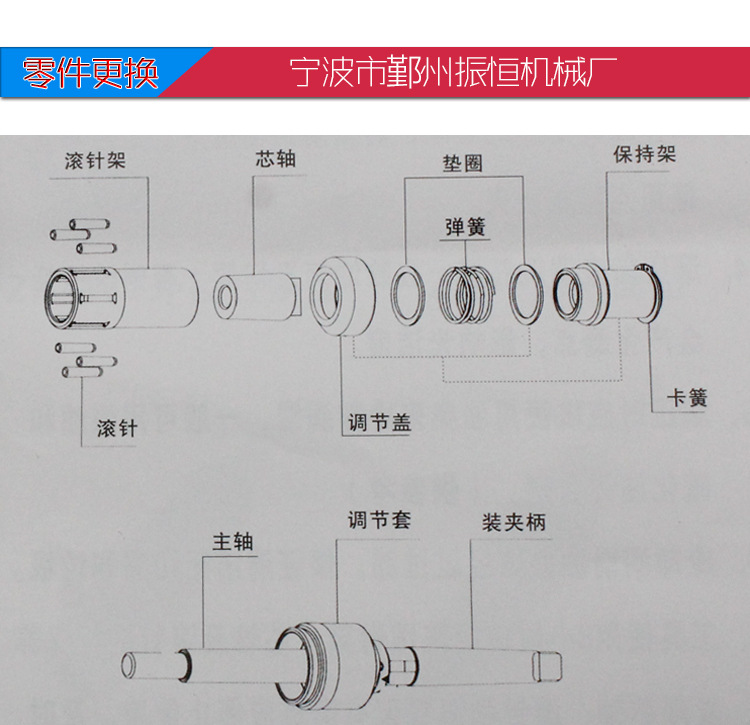

Supply mirror rolling knife rolling head rolling tool squeezing knife. Squeezing knife inner hole rolling knife taper shank/straight shank

Price section

Price from:

2,351,030 so'm

Specifications

φ4-φ5

φ6-φ10

φ11-φ20

φ21-φ30

φ31-φ40

φ41-φ50

φ51-φ60

φ61-φ70

φ71-φ80

φ80-φ90

φ91-φ100

Guaranteed delivery time

If we are 45 days late, you will receive your order for free. More details

Always in touch with you

We will answer any questions every day.

Secure payment in a convenient way

We will accept payment by any card

BNPL available

About the product

Characteristic

- Material

Tool Steel

- Origin

China

- Net weight

1kg

- Name

Rolling Knife

- Brand

Zhenheng

- Scope of application

Machinery. Hardware. Steam. Hydraulic.

- Model

ZH-MK

- Color

Fuchsia

- Weight

1 litre

- Whether to import

No

- Processing customization

Yes

Description

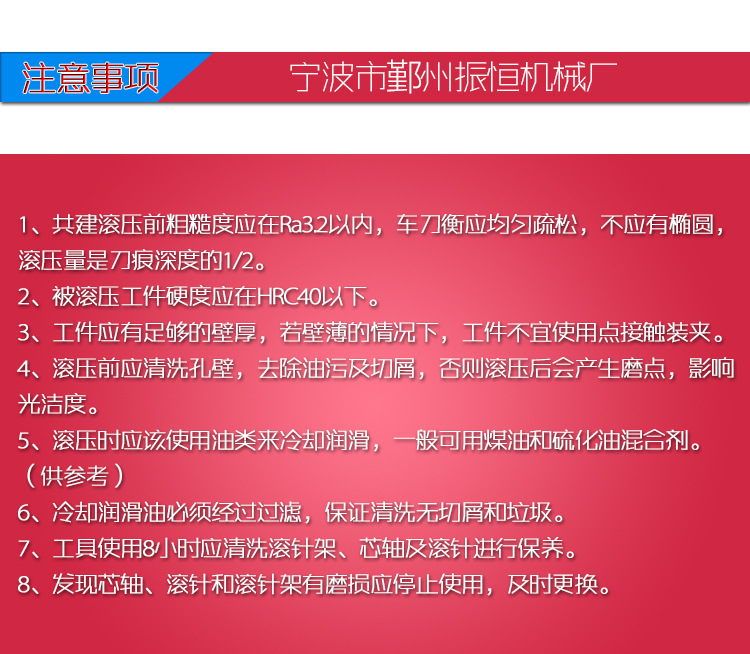

操作方法:

1.工具调整:

(1)用千分尺测量工具顶端直径.

(2)将铝壳向上推动,左右转动,可以调节工具所需要直径,每格刻度值0.0025毫米.

工具使用:

(1)工具可以安装庆车床的尾座上,刀架上,工件旋转,工具不动进行加工,或安装庆铣床,镗床,钻床,加工中心机床主轴上,工件不动,工具旋转进行加工.

(2)工具与工件必须在同一轴线上,以免影响工具的使用寿命.

(3)机床主轴应右转.

(4)工件加工完,工具继续旋转和自动缩小直径,不损伤加工表面退出。

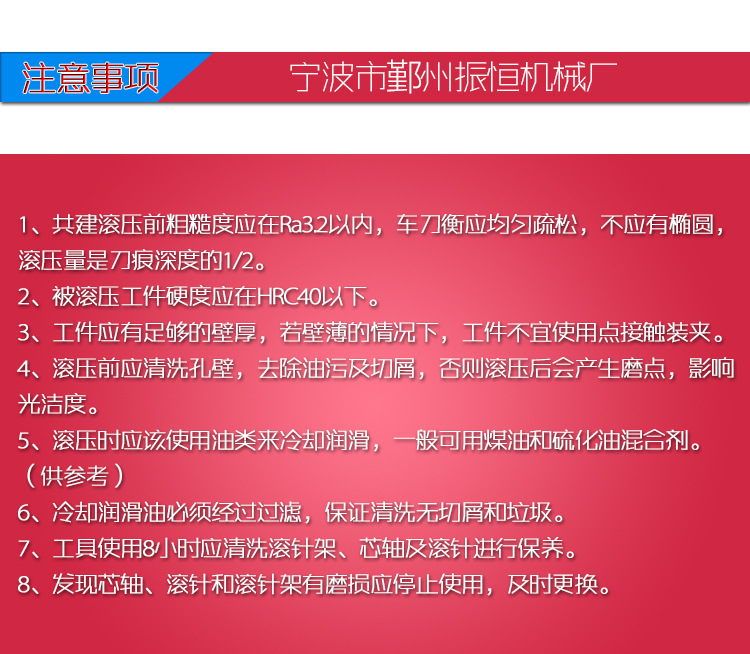

技术参数:

为了获得合适的滚压余量数据,应根据工件本身(主要是材质,硬度,滚压前表面粗糙度等)所选择,在批量加工前应试加工几只产品,调出所要最佳尺寸。

表一:滚压量(供参考)单位:毫米

| 直径 | 8-14 | 15-24 | 25-44 | 45-74 | 75-200 |

| 预留滚压量 | 0.005-0.02 | 0.01-0.03 | 0.02-0.04 | 0.025-0.045 | 0.03-0.06 |

表二:转速,进给量(供参考)单位:毫米

| 工件直径 | 8-14 | 15-24 | 25-44 | 45-74 | 75-99 | 100-139 | 140-200 |

| 转/分 | 1000-500 | 800-400 | 600-300 | 500-300 | 200-80 | 150-50 | 100-40 |

| 毫米/转 | 0.1-0.4 | 0.2-0.6 | 0.3-1.0 | 0.5-1.5 | 0.6-1.8 | 1.2-3.0 | 1.2-3.0 |

Characters

Properties

- Material

Tool Steel

- Origin

China

- Net weight

1kg

- Name

Rolling Knife

Description

操作方法:

1.工具调整:

(1)用千分尺测量工具顶端直径.

(2)将铝壳向上推动,左右转动,可以调节工具所需要直径,每格刻度值0.0025毫米.

工具使用:

(1)工具可以安装庆车床的尾座上,刀架上,工件旋转,工具不动进行加工,或安装庆铣床,镗床,钻床,加工中心机床主轴上,工件不动,工具旋转进行加工.

(2)工具与工件必须在同一轴线上,以免影响工具的使用寿命.

(3)机床主轴应右转.

(4)工件加工完,工具继续旋转和自动缩小直径,不损伤加工表面退出。

技术参数:

为了获得合适的滚压余量数据,应根据工件本身(主要是材质,硬度,滚压前表面粗糙度等)所选择,在批量加工前应试加工几只产品,调出所要最佳尺寸。

表一:滚压量(供参考)单位:毫米

| 直径 | 8-14 | 15-24 | 25-44 | 45-74 | 75-200 |

| 预留滚压量 | 0.005-0.02 | 0.01-0.03 | 0.02-0.04 | 0.025-0.045 | 0.03-0.06 |

表二:转速,进给量(供参考)单位:毫米

| 工件直径 | 8-14 | 15-24 | 25-44 | 45-74 | 75-99 | 100-139 | 140-200 |

| 转/分 | 1000-500 | 800-400 | 600-300 | 500-300 | 200-80 | 150-50 | 100-40 |

| 毫米/转 | 0.1-0.4 | 0.2-0.6 | 0.3-1.0 | 0.5-1.5 | 0.6-1.8 | 1.2-3.0 | 1.2-3.0 |