Welcome to GoBozor

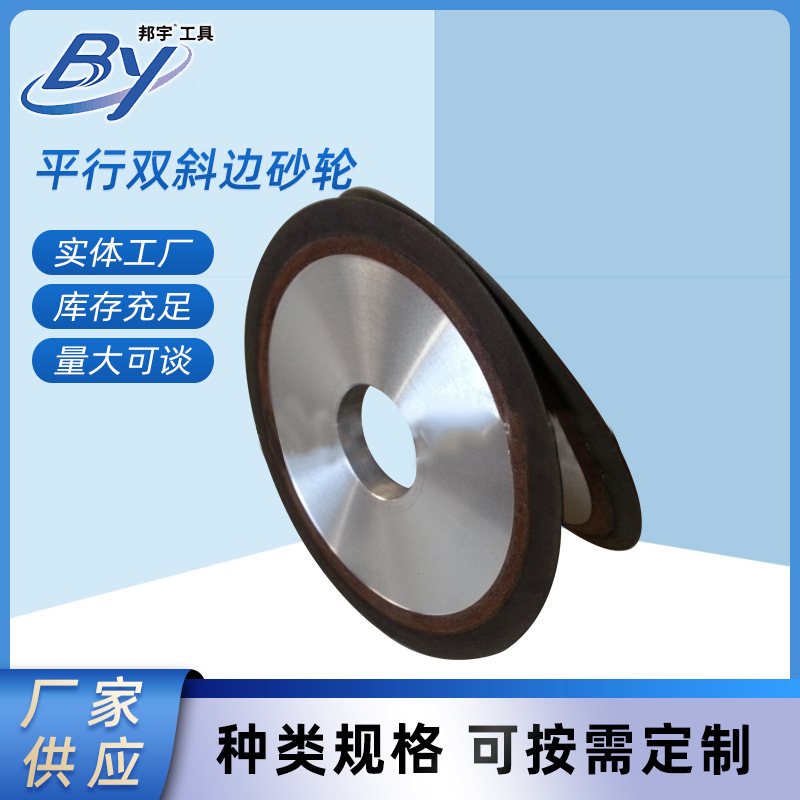

Parallel Double Beveled Grinding Wheel Diamond Grinding Machine Grinding Wheel Titanium Grinding Wheel

0.0

0 sold.

Minimum quantity is: 2 pcs

Price section

Price from:

1,269,557 so'm

Specifications

125×32×32×10×5

1,269,557 so'm

1000 availableGuaranteed delivery time

If we are 45 days late, you will receive your order for free. More details

Always in touch with you

We will answer any questions every day.

Secure payment in a convenient way

We will accept payment by any card

BNPL available

select product

select product

Select payment by installments when placing your order. The final installment cost is calculated at checkout.

Parallel Double Beveled Grinding Wheel Diamond Grinding Machine Grinding Wheel Titanium Grinding Wheel

About the product

Characteristic

- Material

Diamond, cubic boron nitride

- Craft

Sintered

- Type

Tool grinding

- Brand

Bangyu

- Scope of application

Carbide tool, deep hole drill for grinding

- Hardness

Ask customer service

- Maximum speed

Ask customer service

- Processing and customization

Yes

- Cylindrical degree

0.5

- Roundness

0.2

Description

1.磨削效率高,同时砂轮消耗相对较慢;

2.自锐性好,磨削时发热量小,不易堵塞,减少了磨削时出现工作烧伤的现象;

3.砂轮具有的弹性,有利于工件表面的粗糙度,主要用于精磨、半精磨、刀磨、抛光等工序;

4.金刚石树脂砂轮是低温固化,生产周期短,设备和供应流程比较简单;因树脂具有流动性,容易成型复杂性面的砂轮。

Characters

Properties

- Material

Diamond, cubic boron nitride

- Craft

Sintered

- Type

Tool grinding

- Brand

Bangyu

Description

1.磨削效率高,同时砂轮消耗相对较慢;

2.自锐性好,磨削时发热量小,不易堵塞,减少了磨削时出现工作烧伤的现象;

3.砂轮具有的弹性,有利于工件表面的粗糙度,主要用于精磨、半精磨、刀磨、抛光等工序;

4.金刚石树脂砂轮是低温固化,生产周期短,设备和供应流程比较简单;因树脂具有流动性,容易成型复杂性面的砂轮。